Capabilities

DataPro Machining specializes in small to medium-sized projects that require precision manufacturing, tight tolerances, and quick turnaround times. Our is goal to complete your project entirely in-house, and our state-of-the-art manufacturing facility has the flexibility to do so.

Our primary production capabilities are: CNC milling, laser cutting, and sheet metal forming. Post-processing capabilities include: coating, marking, assembly, inspection, and packaging.

We specialize in machining of a wide range of tool steels, titanium and aluminium alloys. We can assist you in sourcing, heat treating and surface grinding these specialty materials to your exact specifications:

- Tool steels: W1, O1, A2, S7, H13, V10 and D2

- Stainless tool steels: 440C, AEB-L, VG10, RWL34, CPM154, S30V, S35VN, S110V, M390, M4, N690, ELMAX

- Titanium alloys: 6AL-4V, 5Al-2.5Sn, and CP (commercially pure) titanium grades: 1, 2, 3 and 4.

- Aluminum alloys: 2011, 2024, 5005, 5052, 6061 and 7075

We can also work with an array of other materials including, but not limited to:

- Plastics: delrin-acetal, acrylic and ABS

- Composites such as carbon fiber

- Copper alloys (such as bronze and brass)

3 Axis Precision CNC Machining

Our machines can reliably deliver parts accurate within +/- 0.0002".

Micro Drilling

With spindles capable of 60,000 rpm, we can accurately and efficiently drill holes as small as 0.001" in diameter.

In-process CNC Inspection

We use a Renishaw probing system for early defect detection and prevention.

Mechanical Engraving and Laser Marking

We achieve highly controlled engraving depth, compliant with MIL-SPEC requirements.

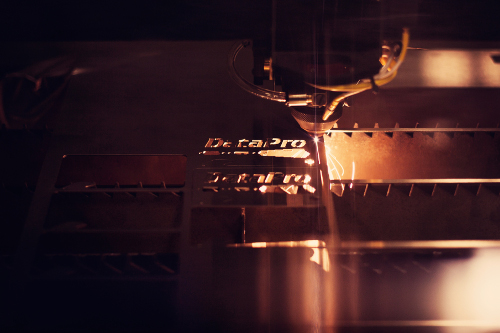

Precision Laser Cutting

Our 400W CO2 laser enables us to precisely cut and mark sheet metals up to 0.09" thick.

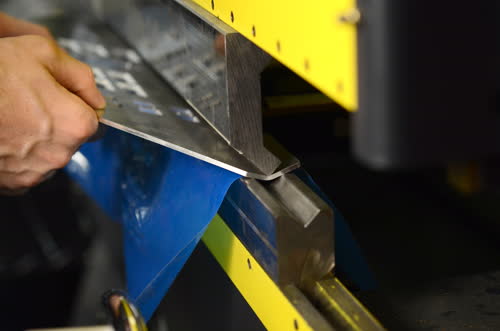

Sheet Metal Bending

We utilize a hydraulic press brake and a box and pan brake, which is ideal for producing custom enclosures with up to 0.125" thick material.

100% Part Quality Control

All parts are comprehensively inspected in our Metrology Department.

Finishing, Abrasive Media Blasting

We offer a range of finishing options including tumbling and abrasive media blasting. Sandblasting pictured above.

Other Capabilities

- 4 Axis indexing

- Broaching

- Anodizing, electroplating, powdercoating

- Heat treating

Assembly

We can provide a product that is tested and assembled to your specifications, so it is ready to use, right out of the box.

Packing & Logistics

DPM's experienced warehouse and shipping personnel will ensure that your products are packed securely and shipped quickly. We ship locally and internationally, using any combination of carriers, couriers, and freight services.